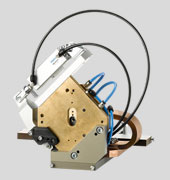

Inverter Schweißstromquellen

Features

(Deutsch)

- wahlweise Mausbedienung oder Touchscreen

- Parallelschalten von bis zu 4 Invertern/Trafos

- wahlweise Strom-, Spannungs- oder Leistungsreglung bzw.Temperaturregelung

- Ansteuerung von 2 Proportionalventilen inklusive Rückführung

- 4 unabhängige Kanäle für Messung beliebiger Analogwerte (z. B. Weg, Kraft)

- 2 Kanäle für inkrementale Wegmessung

- Überwachung aller Eingänge sowie von Strom und Spannung mit Warn- und Eingreifgrenzen, grafisch, nummerisch, SPC-Tendenzverlauf.

- Datenspeicherung in der Steuerung von 100.000 Punkten mit 30 numerischen Werten, Schweißprogramm und jeweils 8 Kurvenverläufen

- Mehrpulsschweißungen mit beliebig vielen unabhängigen Pulsen

- Netzanbindung über Ethernet TCP/IP, digitale E/A, Profinet/SPS, InverterLink, Fernwartung

- Mehrsprachige Bedienung / Protokollierung der Auftragsdaten

Inverter <=> Impulsschweißen

5 Regelarten wählbar

(Deutsch)

- Kondensatorentladung (Leistungsregelung)

- Stromregelung

- Spannungsregelung

- Leistungsregelung

- Temperaturregelung (Option)

- Status Anzeige

- Abnehmbares Bedienteil (Option)

- weitere Details entnehmen Sie bitte dem technischen Datenblatt